Kitchen Operations & Cleanliness Audit: Definition, Importance And How To Conduct

Kitchen operations and cleanliness audit is a systematic evaluation of how a kitchen is managed, from food preparation processes to hygiene protocols, ensuring that every step meets safety and quality standards. Kitchen operations and cleanliness audit also acts as a preventive measure, identifying potential risks, like cross-contamination, poor storage, or improper waste disposal, before they escalate into health hazards. Think of it like the regular servicing of your car: you may not notice a worn-out brake pad until it fails, but routine checks keep you safe on the road; similarly, routine audits keep kitchens compliant and safe for both staff and customers. According to the World Health Organization (WHO, 2023), unsafe food causes over 600 million cases of foodborne illness annually, making regular audits a critical line of defense.

The importance of these audits goes beyond compliance, they build customer trust, protect brand reputation, and maintain operational efficiency. In fact, a study by the US Centers for Disease Control and Prevention (CDC, 2022) found that restaurants with structured hygiene audits had 35% fewer foodborne illness outbreaks compared to those without formal audit systems. This shows that a well-implemented audit is not just a box-ticking exercise but a measurable contributor to public health and business sustainability.

What is a Kitchen Operations and Cleanliness Audit?

A kitchen operations and cleanliness audit is a structured assessment that examines how effectively a kitchen manages its workflow, hygiene practices, food safety protocols, and equipment maintenance. It typically involves reviewing food handling procedures, storage conditions, staff hygiene, pest control measures, waste management, and the overall cleanliness of preparation and serving areas. The goal is to ensure that the kitchen operates in compliance with local health regulations and international food safety standards such as HACCP (Hazard Analysis and Critical Control Points).

These audits are vital because even minor lapses in cleanliness or operational efficiency can have serious health and financial consequences. For example, the Food Standards Agency (UK, 2021) reported that poor hygiene and cross-contamination in food establishments accounted for around 19% of reported foodborne illness cases in the country. Furthermore, a study in the Journal of Food Protection (2020) found that kitchens with regular structured audits had 25% fewer hygiene-related violations during inspections. This data highlights that such audits are proactive strategies for reducing risks, protecting customer health, and safeguarding business reputation.

Why Kitchen Operations and Cleanliness Audits Are Important?

Kitchen operations and cleanliness audits are important for restaurants because they safeguard public health, protect business compliance, and improve day-to-day efficiency. These audits ensure kitchens run smoothly while earning customer trust and meeting legal obligations.

Preventing Foodborne Illnesses

Audits act as an early warning system to detect and eliminate hazards such as improper food storage temperatures, inadequate cooking, or cross-contamination between raw and cooked foods. According to the U.S. Food and Drug Administration (FDA, 2022), keeping foods at safe temperatures (below 5°C or above 60°C) can prevent the growth of harmful bacteria like Salmonella and E. coli, which are linked to thousands of cases of foodborne illness annually. A proactive audit schedule ensures these preventive measures are consistently in place, reducing the likelihood of outbreaks.

Ensuring Legal Compliance

Food safety laws vary by jurisdiction, but failure to comply can result in hefty fines, license suspension, or even permanent closure. Regular audits ensure that operations meet local health codes as well as national and international standards like ISO 22000. A National Restaurant Association (2023) report found that businesses failing to meet regulatory hygiene requirements were 2.7 times more likely to face temporary closure than those with regular compliance checks. This underscores how audits act as insurance against legal and financial risks.

Building Customer Trust

Today’s consumers are more aware of food safety than ever, and transparency breeds loyalty. Displaying a strong audit track record can directly influence customer decisions—research by Mintel (2022) showed that 73% of diners prefer restaurants that can demonstrate verified hygiene and safety measures. By committing to routine audits, restaurants send a clear message: the health of customers comes first.

Improving Operational Efficiency

Audits don’t just protect against health risks; they also streamline kitchen workflows, reduce wastage, and improve resource allocation. For example, an internal audit may reveal duplicated processes, poorly planned storage layouts, or inefficiencies in inventory use. The Foodservice Consultants Society International (FCSI, 2021) found that restaurants implementing operational changes from audit findings improved productivity by 15% within six months. This means audits can directly contribute to both profitability and service quality.

Kitchen operations and cleanliness audits are powerful tools for protecting customers, safeguarding businesses, and improving efficiency. For restaurants, they are an investment in both public health and long-term success.

What Should Be Included in Kitchen Operations and Cleanliness Audits?

Kitchen operations and cleanliness audits should include a comprehensive review of every process, area, and precaution that ensures a safe, efficient, and regulation-compliant kitchen. Covering aspects from food storage to safety hazards, these audits leave no room for oversight, helping prevent health risks, legal issues, and operational inefficiencies.

Food Storage and Handling

Proper storage practices are essential to prevent spoilage and contamination. This involves maintaining safe temperatures, clearly labeling food items, using FIFO (First In, First Out) to manage inventory, and separating raw and cooked foods to avoid cross-contamination. The European Food Safety Authority (EFSA, 2021) found that improper temperature control was a contributing factor in over 23% of reported foodborne illness outbreaks in Europe, highlighting why storage monitoring is a critical audit item.

Cleanliness and Sanitation

All food contact surfaces, utensils, and kitchen areas must be cleaned and sanitized at regular intervals. This includes floors, walls, ceilings, sinks, drains, ovens, refrigerators, and dishwashers. According to the International Journal of Environmental Health Research (2020), kitchens with documented daily sanitation routines had 40% fewer bacterial contamination incidents compared to those without structured cleaning schedules.

Equipment Maintenance

Regular inspection and servicing of kitchen equipment ensures safety and efficiency. This includes checking ventilation systems, repairing faults, and calibrating thermometers. A National Sanitation Foundation (NSF, 2022) study revealed that faulty or poorly maintained equipment accounted for 18% of reported food safety violations in commercial kitchens, making this a vital part of audits.

Employee Hygiene and Training

Staff hygiene has a direct impact on food safety. Employees should practice proper handwashing, wear clean uniforms and PPE such as gloves and hairnets, and undergo training in food handling and cleaning procedures. The World Health Organization (WHO, 2022) notes that up to 20% of foodborne illness outbreaks can be traced back to poor personal hygiene among food handlers.

Pest Control

Audits should check for pest activity, ensure entry points are sealed, and verify that waste disposal methods do not attract pests. A U.S. Environmental Protection Agency (EPA, 2021) report found that pest infestations were responsible for 11% of restaurant closures due to health code violations, showing the importance of preventive measures.

Waste Management

Proper waste segregation, the use of covered bins, and timely disposal prevent odor, contamination, and pest problems. The Food and Agriculture Organization (FAO, 2021) estimates that improper waste handling can increase the risk of pathogen spread in kitchens by up to 30%, making it a necessary audit focus.

Documentation and Record-Keeping

Keeping records of cleaning schedules, temperature logs, equipment maintenance, pest control actions, and staff training ensures accountability and compliance. The Institute of Food Technologists (IFT, 2022) found that businesses with thorough documentation were twice as likely to pass unannounced health inspections as those without it.

Safety Hazards

Audits should also identify potential safety risks such as fire hazards, blocked emergency exits, or poorly stocked first-aid kits. The National Fire Protection Association (NFPA, 2021) reported that cooking equipment is responsible for 61% of fires in eating and drinking establishments, underlining the need for regular hazard checks.

A well-structured kitchen operations and cleanliness audit examines every link in the safety and efficiency chain. By covering these critical areas, restaurants can protect public health, maintain compliance, and ensure smooth, profitable operations.

How To Conduct A Kitchen Operations and Cleanliness Audit?

To conduct kitchen operations and cleanliness audits, one must follow a structured process, which include steps like preparation, on-site inspections, documentation review, detailed reporting, and consistent follow-up to drive improvements.

Preparation

The first step is to define the audit’s scope and objectives, gather relevant documents such as policies, procedures, past reports, and train staff about the audit process. Proper preparation sets the tone for efficiency and accuracy. According to the Chartered Institute of Environmental Health (CIEH, 2022), kitchens with a clearly defined audit plan were 42% more likely to pass official inspections than those without one.

On-Site Inspection

During the inspection, auditors systematically assess kitchen and storage areas, observing operations in real time. This may involve using checklists, taking photographs, and interviewing staff to verify compliance. The Food Safety Authority of Ireland (FSAI, 2021) found that structured on-site inspections with standardized checklists reduced missed compliance issues by 33% compared to informal inspections.

Documentation and Review

The auditor examines temperature logs, cleaning schedules, pest control records, and other operational documents to ensure records match actual practices. A Canadian Food Inspection Agency (CFIA, 2022) study revealed that discrepancies between documentation and on-site conditions were present in 14% of failed inspections, often indicating deeper systemic problems.

Reporting and Recommendations

After the inspection, a comprehensive report is prepared detailing areas of compliance and non-compliance. It includes prioritized recommendations for corrective actions. According to the Institute of Hospitality (2021), audit reports that provide actionable, step-by-step recommendations lead to a 28% faster resolution of non-compliance issues compared to reports that only list violations.

Corrective Actions and Follow-Up

The final stage is implementing corrective measures, documenting actions taken, and scheduling follow-up audits to track progress. The International Association for Food Protection (IAFP, 2022) reported that businesses conducting follow-up audits within 90 days of the initial review saw a 35% higher long-term compliance rate than those without timely follow-ups.

Conducting a kitchen operations and cleanliness audit is a cycle of preparation, inspection, review, and improvement. By following these steps consistently, businesses can maintain high safety standards, meet regulatory requirements, and build a trustworthy reputation.

How Often Should Kitchen Audits Be Conducted?

Kitchen audits should be conducted at regular intervals to maintain hygiene, ensure compliance with food safety regulations, and identify potential hazards before they escalate. The exact schedule depends on the type of establishment, food volume, and legal requirements in the operating region.

Frequency of Audits

The recommended schedule generally includes daily checks for basic cleanliness and food storage, weekly reviews of sanitation practices, monthly inspections for equipment maintenance and pest control, and annual comprehensive audits to evaluate all operational areas. The Australian Institute of Food Safety (AIFS, 2022) advises that high-volume kitchens, such as those in hospitals, hotels, or catering companies, should add monthly formal audits to their daily operational checks because of higher risk and complexity.

Several variables determine how often audits should take place.

- High-risk establishments, like those serving vulnerable populations (children, the elderly, or immunocompromised individuals), require more frequent inspections.

- Kitchens with large-scale food production face greater contamination risks due to increased handling and storage, and thus benefit from shorter audit intervals.

- Local health regulations often mandate specific inspection schedules; for instance, some regions require quarterly audits for catering businesses.

According to the Food Safety Information Council (FSIC, 2021), tailoring audit frequency to risk level can reduce foodborne illness incidents by up to 27%.

Routine vs. Spot Audits

Routine audits are scheduled evaluations that help in maintaining long-term safety standards, while spot audits are unannounced, providing a realistic snapshot of day-to-day practices. Each has unique benefits, routine audits support planning and gradual improvement, while spot checks identify issues that may be hidden during prepared inspections. A Public Health England (2021) study found that surprise inspections detected 21% more hygiene violations than scheduled audits, proving that a combination of both yields the most accurate results.

Kitchen audits should strike a balance between planned reviews and unannounced checks, adjusting their frequency based on the establishment’s risk profile and regulatory framework. This approach ensures continuous safety, compliance, and customer trust.

What Are the Common Issues Found During Kitchen Audits?

The common issues found during kitchen audits are related to cleanliness, storage, workflow efficiency, regulatory compliance, and staff hygiene. Identifying these problems early allows kitchens to take corrective measures, reducing health risks and avoiding costly penalties.

Insufficient Cleanliness

Audits often reveal unclean work surfaces, neglected equipment, and incomplete cleaning routines. These lapses can harbor harmful bacteria and increase the risk of contamination. The Centers for Disease Control and Prevention (CDC, 2021) reported that inadequate cleaning was a contributing factor in over 22% of foodborne outbreaks in commercial kitchens, emphasizing the importance of consistent sanitation.

Poor Food Storage Practices

Incorrect storage temperatures, mixing raw and cooked foods, and keeping expired ingredients are common red flags. Such practices promote bacterial growth and compromise food safety. According to the Canadian Institute of Public Health Inspectors (CIPHI, 2022), improper refrigeration alone accounted for 16% of critical food safety violations in inspected establishments.

Inefficient Kitchen Layout and Workflows

Poorly designed kitchen spaces can cause workflow delays and increase the risk of cross-contamination when clean and dirty processes overlap. The Foodservice Equipment Distributors Association (FEDA, 2021) found that optimizing kitchen layouts for logical movement of staff and materials reduced cross-contamination incidents by 18% in audited kitchens.

Non-Compliance with Food Safety Regulations

Missing hand-washing stations, improper waste disposal, or ignoring temperature checks are frequent compliance failures. Such violations can lead to fines or closures. A U.S. Department of Agriculture (USDA, 2022) study revealed that establishments with repeated non-compliance issues were 3.2 times more likely to face temporary shutdowns compared to those maintaining consistent compliance.

Staff Hygiene and Training Gaps

Improper handwashing, lack of clean uniforms, or insufficient food safety training among staff are recurring problems in audits. The National Institute for Occupational Safety and Health (NIOSH, 2021) highlighted that inadequate staff training contributed to 14% of reported kitchen-related contamination cases, underscoring the need for ongoing education.

Kitchen audits serve as a critical checkpoint for spotting and correcting issues before they escalate into public health risks or legal troubles. Addressing these common problems not only improves safety but also boosts efficiency and customer trust.

What Are the Most Effective Tools and Technologies for Kitchen Operations & Cleanliness Audits?

The most effective tools and technologies for kitchen operations and cleanliness audits are those that simplify inspections, improve record accuracy, and enable real-time monitoring. From specialized audit apps to cloud-based tracking systems, technology helps kitchens stay compliant and efficient while reducing the margin for error.

Popular Audit Tools and Software

Modern kitchen audits are increasingly supported by digital food safety platforms such as Taqtics, iAuditor, and Safefood 360°. These tools provide customizable checklists, automated reminders, and integrated photo documentation, making the inspection process faster and more accurate. According to the Global Food Safety Initiative (GFSI, 2022), organizations using digital audit tools reported 30% shorter inspection times and a 25% reduction in missed compliance points compared to paper-based methods.

Technology for Documentation, Tracking, and Reporting

Cloud-based systems store temperature logs, cleaning schedules, maintenance records, and pest control reports in a centralized location accessible from any device. This eliminates the risk of lost paperwork and ensures data is always up to date. Real-time dashboards allow managers to monitor compliance trends and address issues immediately. The Food Safety Magazine (2021) reported that businesses adopting cloud-based compliance management achieved 40% faster corrective action resolution after audits, as managers could assign and track tasks instantly.

Integrating technology into kitchen operations and cleanliness audits not only streamlines the process but also strengthens accuracy, accountability, and responsiveness. By moving from manual to digital systems, businesses can maintain higher food safety standards with less administrative burden.

Physical Tools and Supplies

Physical tools and supplies are the backbone of effective kitchen operations and cleanliness audits, ensuring that hygiene and safety standards are met on a daily basis. These tangible items allow staff and auditors to measure, monitor, and maintain compliance in real time.

Thermometers

Accurate temperature measurement is essential for preventing bacterial growth in stored and cooked foods. Both probe thermometers for cooked items and infrared thermometers for surface checks are commonly used. The U.S. Food Safety and Inspection Service (FSIS, 2022) emphasizes that keeping food out of the “danger zone” (5°C–60°C) can prevent the majority of bacterial contamination incidents.

Cleaning Checklists

Printed or laminated checklists act as daily reminders for staff to clean specific areas and equipment. They also provide a record of completed tasks for auditors to review. The Chartered Institute of Environmental Health (CIEH, 2021) notes that kitchens using structured cleaning checklists had 34% fewer sanitation-related violations during inspections.

Pest Traps

Rodent and insect traps placed in strategic areas help detect and control pest activity before it becomes an infestation. These tools provide visible evidence of pest monitoring, which is a critical compliance requirement. The National Pest Management Association (NPMA, 2022) found that consistent use of pest traps reduced pest-related violations by 27% in food service environments.

Sanitation Supplies

Disinfectants, sanitizing sprays, cleaning cloths, brushes, and mops are essential for maintaining hygiene. Color-coded cleaning tools can further prevent cross-contamination between areas such as raw food prep zones and service counters. The International Association for Food Protection (IAFP, 2021) reported that kitchens with well-maintained sanitation supplies achieved 20% faster cleaning turnaround times without compromising hygiene quality.

Physical tools and supplies like thermometers, checklists, pest traps, and sanitation equipment are critical safeguards. Their consistent use ensures food safety compliance, operational efficiency, and a clean, trustworthy kitchen environment.

How Can You Involve Your Staff in the Kitchen Operations & Cleanliness Audit Process?

You can involve your staff in kitchen operations and cleanliness audit process by building their knowledge of food safety standards and actively engaging them in each stage of the audit. This not only boosts compliance but also creates a shared sense of responsibility for maintaining a safe and hygienic kitchen environment.

Training and Awareness

Educating staff on food safety and hygiene practices is the foundation of a successful audit. Training sessions should cover critical areas like temperature control, cross-contamination prevention, cleaning protocols, and personal hygiene.

- Clear instructions and regular refreshers ensure that employees understand the “why” behind the rules, making them more likely to follow procedures consistently.

- Engaging staff during the audit means involving them in tasks such as completing cleaning checklists, recording temperature logs, or accompanying auditors during inspections to answer process-related questions. This hands-on involvement fosters ownership and transparency.

- According to a Food Standards Australia New Zealand (FSANZ, 2021) study, kitchens where staff participated in audits showed 19% fewer recurring violations because employees were directly accountable for their work areas.

- Managers can further encourage participation by recognizing staff contributions and providing feedback after each audit.

Staff involvement turns kitchen audits into a collaborative process rather than a top-down inspection. When employees are trained, engaged, and accountable, audit results improve and so does the overall culture of food safety.

The National Restaurant Association (2022) found that restaurants providing structured food safety training to all employees achieved 26% higher compliance scores during inspections compared to those with ad-hoc training.

How Can You Ensure a Successful Kitchen Operations & Cleanliness Audit?

You can ensure a successful kitchen operations and cleanliness audit by setting clear expectations, fostering a strong culture of cleanliness, and regularly updating procedures to align with changing regulations and operational demands.

Setting Clear Expectations for Audits

Before an audit, clearly outline its purpose, scope, and evaluation criteria to all staff. This ensures everyone knows what will be assessed and what standards must be met. The Hospitality Institute of Technology and Management (HITM, 2022) found that establishments with transparent audit expectations achieved 22% fewer non-compliance issues than those where staff were unclear about audit requirements. Regular pre-audit briefings and visible checklists keep the team aligned.

Creating a Culture of Cleanliness and Food Safety

A one-time cleaning spree before an audit is no substitute for an ingrained safety culture. This means promoting daily habits, like proper handwashing, immediate spill clean-ups, and consistent equipment sanitizing, as standard operating procedure. According to the European Food Information Council (EUFIC, 2021), kitchens with a documented “clean-as-you-go” policy experienced 29% fewer hygiene violations during inspections. By rewarding consistent behavior, management can reinforce these practices year-round.

Regular Review and Updating of Audit Procedures

Regulations, equipment, and menu offerings can change over time, making it essential to update audit processes accordingly. Regular reviews ensure that checklists, training materials, and compliance protocols reflect the latest industry standards. A Canadian Restaurant and Food Services Association (CRFA, 2022) survey revealed that restaurants updating their audit processes at least twice a year were 31% more likely to maintain top-tier compliance ratings than those with static procedures.

A successful kitchen operations and cleanliness audit is the product of clear communication, a deeply rooted safety culture, and continuous process improvement. This approach not only satisfies inspectors but also safeguards customer health and strengthens the restaurant’s reputation.

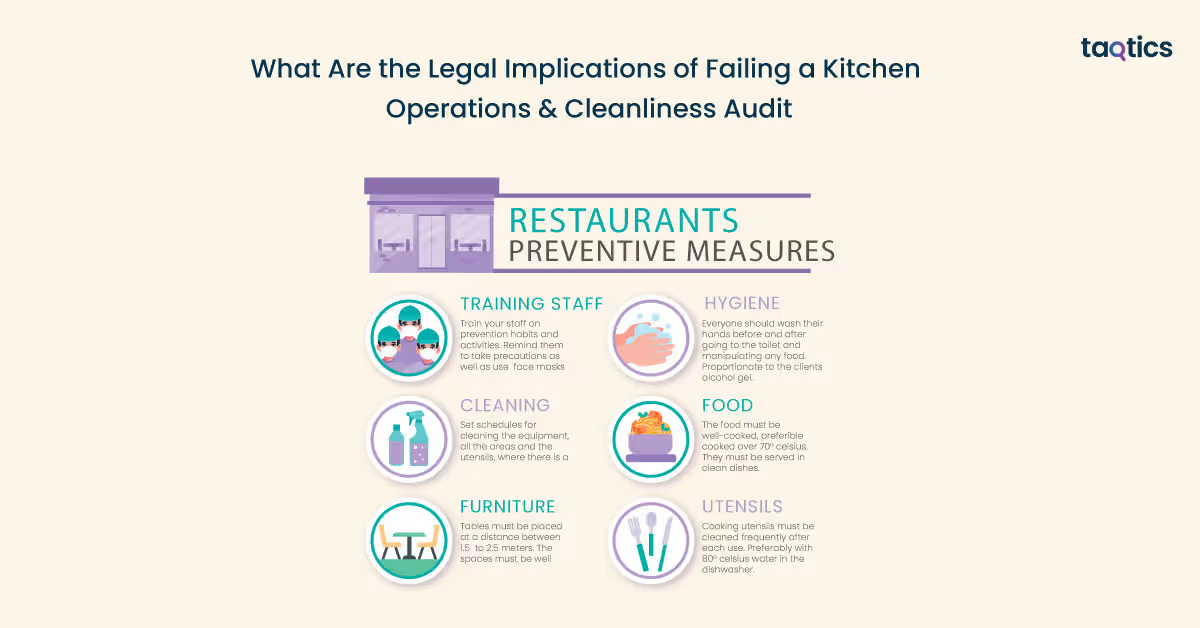

What Are the Legal Implications of Failing a Kitchen Operations & Cleanliness Audit?

The legal implications of failing a kitchen operations and cleanliness audit in India are governed by the Food Safety and Standards Act, 2006 and enforced by the Food Safety and Standards Authority of India (FSSAI). A failed audit can lead to monetary fines, license suspension or cancellation, and even criminal prosecution in severe cases, making compliance not just a best practice but a legal necessity.

Fines and Monetary Penalties

Under the FSSAI regulations, failing to meet hygiene and operational standards can result in substantial fines. For example:

- ₹1 lakh for sub-standard food

- ₹5 lakh for misbranded food

- ₹10 lakh for food containing unsafe substances harmful to health (FSSAI, 2023)

The exact amount depends on the severity of non-compliance and whether it poses an immediate public health risk.

Suspension or Cancellation of FSSAI License

If an audit reveals critical violations such as pest infestations, unsafe storage, or cross-contamination, the Designated Officer can suspend operations until compliance is restored. Repeated failures may lead to permanent cancellation of the FSSAI license, effectively shutting down the business. The FSSAI Annual Report (2022) recorded over 2,800 licenses suspended or cancelled in a single year due to non-compliance with food safety norms.

Criminal Liability

In cases where violations result in serious injury or death, the Act prescribes imprisonment ranging from six months to life, depending on the outcome and level of negligence. For example, Section 59 allows for jail terms if unsafe food causes harm, with fines reaching up to ₹10 lakh.

Civil Lawsuits and Compensation

Consumers can file cases in consumer courts seeking compensation for health damage caused by unsafe food. Under the Consumer Protection Act, 2019, compensation amounts can be substantial, particularly in high-profile cases involving widespread illness.

Reputational Damage and Business Impact

A failed audit often results in negative publicity, especially when reported by local health authorities or media. Public disclosure of hygiene ratings under FSSAI’s Eat Right India initiative means that poor scores can directly impact customer footfall and trust.

Failing a kitchen operations and cleanliness audit in India can have far-reaching consequences, including financial, legal, and reputational. For restaurants, cloud kitchens, and catering units, maintaining FSSAI-mandated hygiene standards ensures customer safety, protects the business, and sustains long-term growth.