5S & Lean Manufacturing: Definition, Importance & Steps

5S and lean manufacturing are systematic approaches aimed at organizing workplaces, reducing waste, and improving operational efficiency by creating order, consistency, and discipline on the shop floor. 5S and lean manufacturing focus on eliminating non-value-adding activities so that people, materials, and information flow smoothly with minimal delays or errors.

5S works much like organizing a home kitchen where utensils are sorted, labeled, kept clean, and returned to their designated places so that cooking becomes faster and less stressful. Lean manufacturing applies the same logic at scale in factories, helping teams save time and reduce rework. A study published in the International Journal of Lean Six Sigma (2016) reported productivity improvements of up to 30% after structured 5S implementation, while Womack and Jones’ foundational lean research in Lean Thinking (1996) highlighted significant reductions in lead time and operational waste across manufacturing industries.

What Is 5S in Lean Manufacturing?

5S is a workplace organization methodology that originated in the Toyota Production System (TPS) in Japan. The term represents five Japanese principles: Seiri (Sort), Seiton (Set in Order), Seiso (Shine), Seiketsu (Standardize), and Shitsuke (Sustain), designed to create a clean, efficient, and well-organized work environment that supports consistent performance and quality.

Lean manufacturing is a management philosophy focused on eliminating waste (muda), improving process flow, and maximizing value for the customer while using fewer resources. Lean emphasizes continuous improvement, employee involvement, and data-driven decision-making across production and support processes.

5S fits within Lean as a foundational practice that enables other Lean tools to function effectively. By organizing the workplace and standardizing routines, 5S improves visibility, reduces motion and waiting waste, enhances safety, and creates the discipline needed for advanced Lean practices such as Kaizen, Just-in-Time, and Total Productive Maintenance (TPM).

Why Is 5S Important in Manufacturing?

5S is important in manufacturing because it lays the foundation for a clean, organized, and efficient work environment, directly impacting productivity, safety, and product quality.

- Improved Efficiency: Streamlined workflows and reduced motion waste enable faster production cycles and lower operational costs.

- Enhanced Safety: A tidy, well-marked workspace prevents accidents, equipment damage, and occupational hazards.

- Higher Quality: Consistent organization reduces defects caused by misplaced tools, materials, or inconsistent processes.

- Support for Lean Goals: 5S directly contributes to Lean objectives by eliminating non-value-adding activities, optimizing resource utilization, and maximizing value for the customer.

By embedding 5S into daily routines, manufacturers create a culture of continuous improvement that strengthens Lean initiatives and delivers tangible operational benefits.

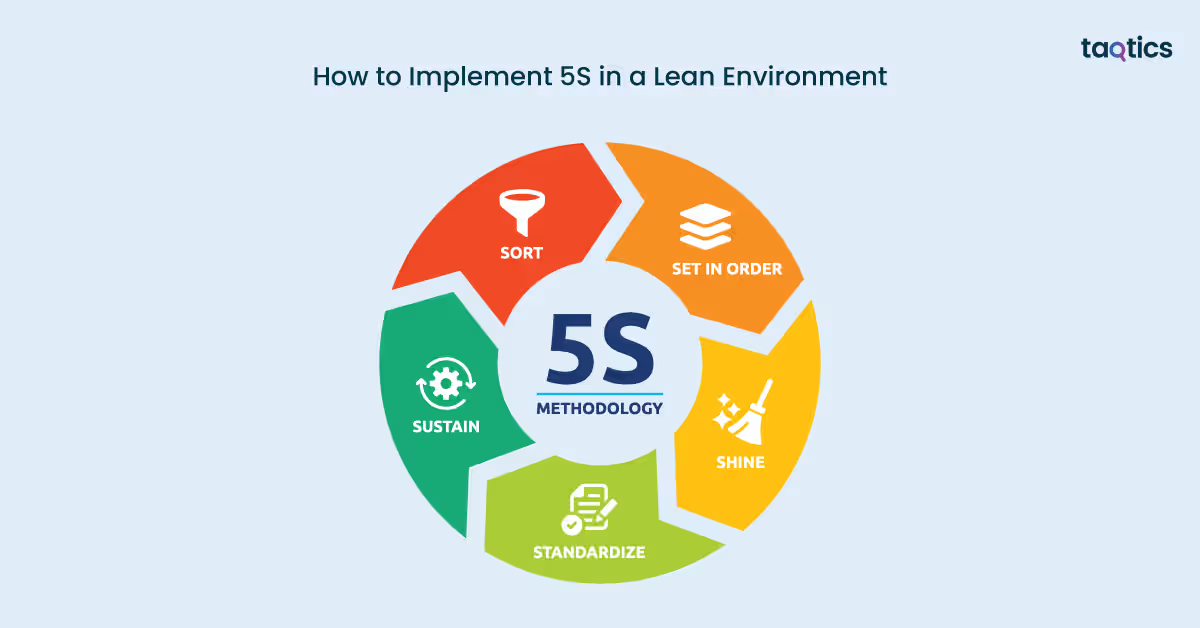

What Are the 5S Steps in Lean?

The 5S steps in lean are Sort (Seiri), Set in Order (Seiton), Shine (Seiso), Standardize (Seiketsu), and Sustain (Shitsuke), each designed to create a systematic, organized, and efficient workplace.

1. Sort (Seiri)

Sorting involves identifying and separating necessary items from unnecessary ones in the workspace. Tools, materials, and documents that are not required for current operations are removed or relocated. This reduces clutter, frees up space, and prevents confusion or mistakes, allowing employees to focus only on what adds value.

2. Set in Order (Seiton)

Set in Order focuses on arranging tools, equipment, and materials in logical and easily accessible locations. Implementing labeling, color-coding, and visual cues ensures that every item has a designated place. This step minimizes time spent searching for items and improves workflow efficiency.

3. Shine (Seiso)

Shine emphasizes cleaning the workplace and equipment regularly to maintain operational readiness. It involves identifying and addressing sources of dirt, spills, or maintenance issues. A clean environment not only supports safety but also prevents equipment failures and ensures smooth production processes.

4. Standardize (Seiketsu)

Standardize establishes uniform procedures and schedules for sorting, organizing, and cleaning. Tools such as checklists, visual guides, and documented routines help ensure consistency across shifts and departments. Standardization makes deviations easy to spot and correct, reinforcing best practices.

5. Sustain (Shitsuke)

Sustain is about cultivating a culture of discipline and continuous improvement to maintain 5S practices over the long term. Regular audits, employee training, and accountability measures help embed 5S into daily routines. Sustaining these practices ensures ongoing efficiency, safety, and quality improvements while supporting broader Lean goals.

These five steps together form a continuous cycle, where sustained organization and discipline drive efficiency, safety, and quality improvements across the manufacturing process.

How Does 5S Improve Operational Efficiency?

5S improves operational efficiency by creating an organized, clutter-free, and standardized workplace that allows materials, tools, and information to flow smoothly through production processes.

Enhanced Workflow and Reduced Downtime: By sorting and setting items in order, 5S minimizes motion waste and prevents bottlenecks in production. Equipment and tools are readily accessible, and maintenance issues are identified earlier through regular cleaning (Shine), ensuring machines operate at peak performance and unplanned stops are minimized.

Faster Changeovers: Standardized processes and visual cues allow teams to quickly switch between production batches or product types. This reduces setup times and enables more flexible manufacturing schedules, supporting Lean principles like Just-in-Time production.

Improved Quality and Employee Morale: A well-organized and clean workspace reduces errors, defects, and contamination, directly enhancing product quality. Employees also benefit from a safer, more predictable work environment, which boosts morale, engagement, and ownership of processes. Studies have shown that organizations implementing 5S report up to 30–40% improvement in productivity and higher employee satisfaction due to reduced frustration and smoother operations.

By streamlining workflows, standardizing practices, and fostering a disciplined culture, 5S directly contributes to faster, safer, and higher-quality manufacturing operations.

How to Implement 5S in a Lean Environment?

To implement 5S in a lean environment, you can follow a structured approach that ensures each step builds on the previous one, creating a smooth and sustainable improvement in workplace organization and efficiency.

- Begin by assessing current conditions to identify clutter, inefficiencies, and safety risks, which provides a baseline for measuring progress. This initial evaluation helps prioritize areas where 5S implementation will have the greatest impact.

- The next step is to Sort (Seiri) by removing unnecessary items and keeping only what is essential for operations.

- Once unnecessary items are eliminated, Set in Order (Seiton) by arranging tools, materials, and equipment in logical, easily accessible locations. Use labeling, color-coding, and visual cues to make the system intuitive and reduce wasted time searching for items.

- After organizing, focus on Shine (Seiso) and regularly clean and inspect work areas, machinery, and storage spaces. This not only maintains operational readiness but also helps identify potential maintenance issues before they cause downtime.

- Once sorting, organizing, and cleaning are established, it is important to Standardize (Seiketsu) these practices by creating clear procedures, schedules, and visual guides. Standardization ensures consistency across shifts and departments, making it easier to spot deviations and maintain efficiency.

- Finally, Sustain (Shitsuke) the 5S process by cultivating discipline through regular audits, checklists, and accountability measures.

Continuous reinforcement of these practices embeds 5S into daily routines, supporting broader Lean objectives like waste reduction, flow optimization, and quality improvement.

Employee engagement is critical throughout the implementation process. Training sessions help staff understand the principles, benefits, and practical applications of 5S, while involving them in planning and decision-making increases ownership and commitment. Visual management tools, posters, or digital dashboards can reinforce best practices daily.

What Are Common 5S Tools and Templates?

The common 5S tools and templates are designed to make the implementation of 5S easier, more consistent, and measurable across all areas of a manufacturing or operational environment.

- Printable 5S checklists: Guide employees through daily, weekly, or monthly sorting, cleaning, and inspection tasks; provide documentation for audits and continuous improvement.

- Visual boards (Kanban): Display workflow, inventory levels, and task status at a glance; improve coordination and reduce delays.

- Standard operating procedures (SOPs): Document step-by-step processes for organizing, cleaning, and maintaining workspaces; ensure consistency across teams and shifts.

- Digital alternatives: Mobile apps or software that offer real-time audit logging, automated reminders, dashboards, and cloud-based documentation; streamline reporting and track compliance across multiple sites.

These tools and templates create a robust support system for implementing and sustaining 5S, helping organizations maintain an organized, efficient, and continuously improving workplace.

How Can Software Like Taqtics Help With 5S and Lean Manufacturing?

A software like Taqtics can help with 5S and lean manufacturing by digitizing and automating key processes, making it easier to implement, monitor, and sustain 5S practices while supporting broader Lean goals. By centralizing data and providing actionable insights, Taqtics ensures that workplace organization, safety, and efficiency improvements are tracked consistently across all areas of production.

- 5S Checklists: Taqtics allows creation of customizable digital checklists for sorting, organizing, cleaning, and maintaining workspaces, ensuring tasks are completed consistently and documented automatically.

- Visual Management Dashboards: The platform provides real-time dashboards to track workplace organization, audit results, and progress on Lean initiatives, making inefficiencies and deviations immediately visible.

- Audit Tracking: Taqtics enables scheduled and on-demand audits, recording results digitally with timestamps, photos, and comments, which improves accountability and reduces manual reporting.

- Real-Time Data Collection: Temperature, humidity, and other operational metrics can be logged in real time, helping teams maintain optimal conditions, detect deviations quickly, and take corrective action.

A mid-sized electronics manufacturer implemented Taqtics to manage 5S across multiple production lines. Employees used mobile devices to complete digital checklists, while supervisors monitored progress via dashboards. Within three months, audit compliance increased by 40%, setup times decreased, and workplace organization became visibly more consistent, demonstrating how Taqtics simplifies 5S implementation while supporting Lean efficiency.

How Do You Audit 5S Processes?

You audit 5S processes by systematically evaluating workplace organization, cleanliness, and adherence to standardized procedures to ensure that 5S practices are effectively implemented and sustained. The purpose of these audits is to identify gaps, prevent inefficiencies, improve safety, and support continuous improvement within Lean manufacturing. Regular audits help maintain discipline, track progress, and provide data for corrective actions.

A sample 5S audit checklist helps you answer some essential questions.

- Sort (Seiri): Are unnecessary items removed from the workspace?

- Set in Order (Seiton): Are tools and materials organized and labeled properly?

- Shine (Seiso): Are work areas and equipment clean and inspected regularly?

- Standardize (Seiketsu): Are procedures and schedules for 5S being followed consistently?

- Sustain (Shitsuke): Are employees trained and adhering to 5S practices?

Using a software like Taqtics can greatly simplify 5S audits. Digital checklists, automated reminders, and real-time tracking allow audits to be conducted efficiently on mobile devices, while dashboards provide instant visibility of compliance status. This reduces manual effort, ensures accurate record-keeping, and makes it easier to follow up on corrective actions, keeping 5S practices consistent and effective across all areas of the organization.

What Is the Difference Between 5S and Lean Manufacturing?

The difference between 5S and lean manufacturing lies in their scope, purpose, and application, even though both aim to improve efficiency, quality, and operational performance.

| Aspect | 5S | Lean Manufacturing |

| Definition | Workplace organization methodology to create clean, orderly, and standardized work areas. | Comprehensive production philosophy aimed at eliminating waste and maximizing customer value. |

| Scope | Focuses on individual workspaces and immediate operational areas. | Applies to the entire production process, supply chain, and organizational culture. |

| Purpose | Improve order, cleanliness, safety, and process consistency. | Reduce all forms of waste, optimize workflow, and enhance overall efficiency. |

| Implementation | Involves five steps: Sort, Set in Order, Shine, Standardize, Sustain. | Uses Lean tools such as Just-in-Time (JIT), Kaizen, Value Stream Mapping, and Total Productive Maintenance (TPM). |

| Metrics | 5S compliance scores, audit results, and workspace condition. | Cycle times, defect rates, inventory levels, throughput, and customer value delivered. |

| Relationship | Often, a foundational step within Lean initiatives. | A broader philosophy that includes 5S as one of its building blocks. |

This comparison shows that while 5S ensures an organized and disciplined workplace, Lean manufacturing focuses on streamlining processes and maximizing efficiency across the entire organization.